Flooring Solutions

ResCom® Sub-floor & Finished Floor Products are eco-friendly and do not off-gas any known contaminates. It contains zero TVOCs and no Formaldehyde.

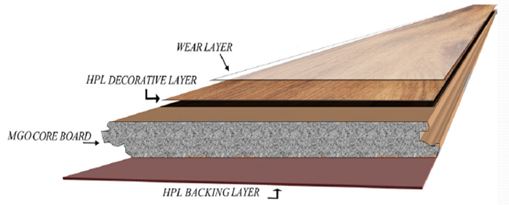

ResCom® Floor Materials are available in many designs and provide a water-resistant, non-combustible, wood-floor substitute for laminated wood floor products. A protective (wear-layer) increases the lifecycle and prevents curling.

Structural Flooring Range (SF)

Intended Use: Commercial and Residential

Testing and Compliance: Independently tested at ILAC-accredited third-party laboratories as required by the National Construction Codes (NCC) of Australia, New Zealand, North America, United Kingdom, Ireland, and UAE (Refer to tested standards and reports online at www.rescombp.com)

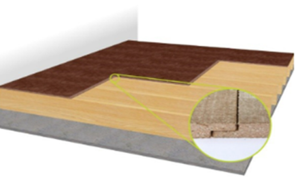

Applications: Loadbearing and Non-Loadbearing Structural Flooring Systems

Spans: 400mm o/c, 450mm o/c, 600mm o/c

Young’s Modulus 20mm AS/NZS:2908.2-2000: Average 5.56Gpa

Modulus of Rupture 20mm AS/NZS:2908.2-2000: Average 6.40Mpa

Transverse Load-Floor 20mm ASTM:E72-22 & ASTM:E2322-22 Sec 10 Span 450mm: 9.75(kN) average

Concentrated Load-Floor 20mm ASTM:E72-22 & ASTM:E2322-22 Sec 11: Average Deflection 0.24mm

Concentrated Load-Floor 20mm ASTM:E72-22 & ASTM:E2322-22 Sec 11: Average Indentation 0.03mm

Performance: Water resistant, Impact resistant, Mold resistant, Non-Toxic

Fire Performance: A1 / Group A Non-Combustible

Incipient Spread of Flame: Zero

Bushfire / Wildfire Zones: Meets and exceeds BAL:29 to BAL: FZ Ratings

Color: Dark Gray / Brown

Thicknesses: 16mm to 20mm

Lengths in Imperial / Metric: 1800mm, 2400mm, 2700mm, and 3000mm

Width in Imperial / Metric: 600mm, 900mm, and 1200mm

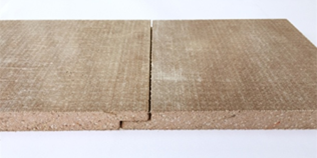

Edge Profiles: Ship Lap or Square Edge

Workability: Circular saw with a diamond blade. Able to be routed and profiled by hand or by CNC.

Can be sanded, rendered, painted, epoxy coated, or tiled

Toxicity: Zero TVOCs, No Benzines, No Formaldehyde

| Thickness | Joist Centres |

Test Criteria |

Pressure Result |

Point Load Result |

Pont Load 1.0kN |

|---|---|---|---|---|---|

| 16mm | 400mm | 1.5 kPa 1.8 kN |

0.6036mm SF>12 |

0.73mm SF>3 |

<0.5mm SF>3 |

| 18mm | 400mm | 2.0 kPa 1.8 kN |

0.058mm SF>12 |

0.76mm SF>3 |

<0.5mm SF>3 |

| 18mm | 450mm | 2.0 kPa 1.8 kN |

0.084mm SF>12 |

0.84mm SF>3 |

<0.5mm SF>3 |

| 19mm | 450mm | 2.0 kPa 1.8 kN |

0.078 mm SF>12 |

0.78mm SF>3 |

<0.5mm SF>3 |

| 20mm | 450mm | 3.0 kPa 2.7 kN |

0.10 mm SF>12 |

1.08mm SF>3 |

<0.5mm SF>3 |

| 20mm | 600mm | 3.0 kPa 2.7 kN |

0.330 mm SF>12 |

1.9mm SF>3 |

<0.5mm SF>3 |

| 25mm | 450mm | 5.0 kPa 4.5 kN |

0.09mm SF>12 |

1.0mm SF>3 |

<0.5mm SF>3 |

| 25mm | 600mm | 3.0 kPa 2.7 kN |

0.004mm SF>12 |

1.0mm SF>3 |

<0.5mm SF>3 |