Fire Resistance

Class A non-combustible is a non-flammable building material that has almost no burn. It is a fire-resistant material that is used in high-rise buildings.

“ResCom®” silicon crystal inorganic prefabricated panels have no combustion droplets or particles within 600 seconds at high temperatures. The panels will not break, deform, peel, or form bubbles under these conditions. The test results show that the panels comply with the fire-resistance Class A (A2-S1, D0) and GB8624-12 requirements. The panels effectively prevent the occurrence and spread of fires. Making them particularly suitable for use in indoor areas with high fire-resistance requirements and dense pedestrian traffic, such as schools, hospitals, subway stations, stadiums, airports, tunnels, hotels, and shopping malls, etc.

TESTING CRITERIA AND PROTOCOL

INTERNATIONAL LABORATORY ACCREDITATION COOPERATION (ILAC): ILAC is a global network of accreditation bodies that recognize each other’s accreditations through the ILAC Mutual Recognition Arrangement (MRA). This arrangement promotes the acceptance of test and calibration data across national borders, reducing the need for duplicate testing.

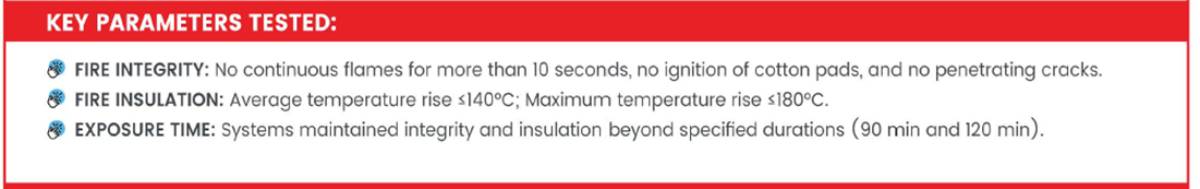

The testing of these systems has been conducted in accordance with globally recognized standards, including:

- GB/T 9978.1-2008 &. GB/T 9978.8-2008 (China)

- AS/NZS 1530.4 (Australia/New Zealand)

- BS/EU 476 (United Kingdom/European Union)

- ASTM E119, ASTM E84 and ASTM E136 (North America)

- UL 263 (Underwriters Laboratories, USA)

These standards evaluate fire integrity, fire insulation, and temperature rise performance, ensuring that the systems meet stringent criteria for non-combustibility and fire resistance. Classifications suitable for critical infrastructure, commercial, and residential applications.

■ Duration:90 minutes ■ Average Temp Rise: 64°C ■ Maximum Temp Rise: 89°C

■ Compliance: Fully compliant with AS/NZS 1530.4, BS/EU 476, ASTM E119, and UL 263.

Fire-Resistant Performance:

CELLULOSE MAGNESIA CEMENT (CMC) RESIDENTIAL – COMMERCIAL – INDUSTRIAL

HIGH PERFORMANCE: INTERIOR | EXTERIOR

- Combustibility: Class A non-flammable material

- Fire Endurance: 1-3 hours

- The smoke-forming toxin is graded as ZA, which is non-toxic.

High-Strength Mechanical Properties:

- High folding strength: greater than 8MPa (plate thickness 3-18mm, density l-l.Sg/cm3, four layers of 120g / glass fiber cloth reinforcement, the folding strength can reach 64MPa by the reinforcement of multi-layer glass fiber cloth)

- The compressive strength is 90MPa. impact resistance refers to

- hard impact: the use of a 1000g steel ball to freely fall from 1 m above the panels, then the surface of the panel products shall be free of cracks and flaking. The shock strength with the impact tester is 6.SKJ/ (Standard is greater than or equal to 2.0 KJ/)

- The dry shrinkage rate is 0.3%, and the wet swelling rate is 0.6%.